▼Measurement indicators

Basis weight (g/m2), thickness (μm).

▼Application areas

Paper, film, nonwovens, cloth, metal foil and other web materials.

▼Main components

The isotope radiation sensor consists of two parts: the transmitter and the receiver.

The transmitter head mainly includes: transmitter head box, isotope radiation source (Kr85 or Pm147), lead sealed container, micro guide rail, single-acting cylinder, magnetic proximity switch, controlled measurement window, etc.

The receiving head mainly includes: a receiving head box, an ionization chamber, a DC high-voltage power supply, a signal amplifier circuit board, a signal processing circuit board, a communication circuit board, a measuring window film, etc.

▼Measurement principle

The absorption attenuation of β-rays passing through materials approximately obeys Beer's law as the theoretical basis; the sensor transmitter controls the measurement window to emit β-rays, which pass through the measured medium and enter the receiving head. The ionization chamber and electronic circuit in the receiving probe receive the rays that are absorbed and weakened by the measured material and convert them into electrical signals proportional to the intensity of the received rays. By establishing a mathematical model between the measured medium (surface density) and the measured electrical signal, the nonlinear function constant is determined by fitting the relationship between the measured medium and the signal with big data.

In applied measurement, the surface density of the measured medium is calculated using the measurement signal function interpolation method.

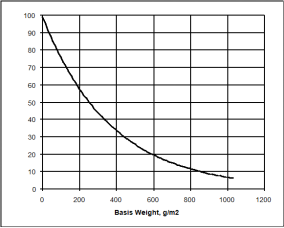

Figure 1: Relationship between the attenuation intensity of the radiation source signal and the surface density of the object being measured

Beer's law of absorption of β rays through matter: I=Io*exp(-μ*BW)

I = sensor signal with the object being measured, Io = sensor signal with no gap; BW = surface density, μ = mass absorption coefficient.

▼Technical features

◆ Normally closed cylinder direct-push shutter, automatically closes the radiation source in the event of equipment failure.

◆ The lead can seals the radiation source tightly, and the environmental radiation index is reached within a range of 30cm.

◆ 8-15mm measurement gap, shortest ray air path and lowest environmental interference.

◆ The type of beta ionization chamber matches the energy spectrum of the radiation source, with high sensitivity and wide linearity.

◆ Precision microelectronic circuit, high stability, high signal-to-noise ratio and large dynamic range.

◆ The receiving gain can be controlled in different levels to adapt to the attenuation of the radiation source and maintain good signal quality.

◆ The receiving chamber is heated at a constant temperature and the measuring window is protected from condensation to ensure the stability of the measuring environment parameters.

◆ Not affected by material composition, color, density, thickness, and directly reflects the measured physical indicators.

◆ Online transmission non-destructive testing.

▼Performance indicators